Empire Cartridges, Techman TM5 Cobot Integration

Through the “Made Smarter” government funding initiative, Morson Praxis supported Empire Cartridges in transforming their production capabilities with Industry 4.0 technology. The investment enabled the company to significantly upscale their manufacturing operations, reaching the capacity to produce and pack over one million shotgun cartridge shells annually.

Client Brief

Automating for Efficiency and Growth

Empire Cartridges sought to modernise and streamline their cartridge production process. Their goal was to automate manual packaging tasks, boost efficiency, and improve consistency across their manufacturing line.

Project Overview

Integrating Industry 4.0 Technologies for Scalable Production

Morson Praxis worked with Empire Cartridges to identify opportunities for automation and digital transformation within their production process. By integrating smart manufacturing technologies, the project aimed to create a more efficient, scalable, and cost-effective operation.

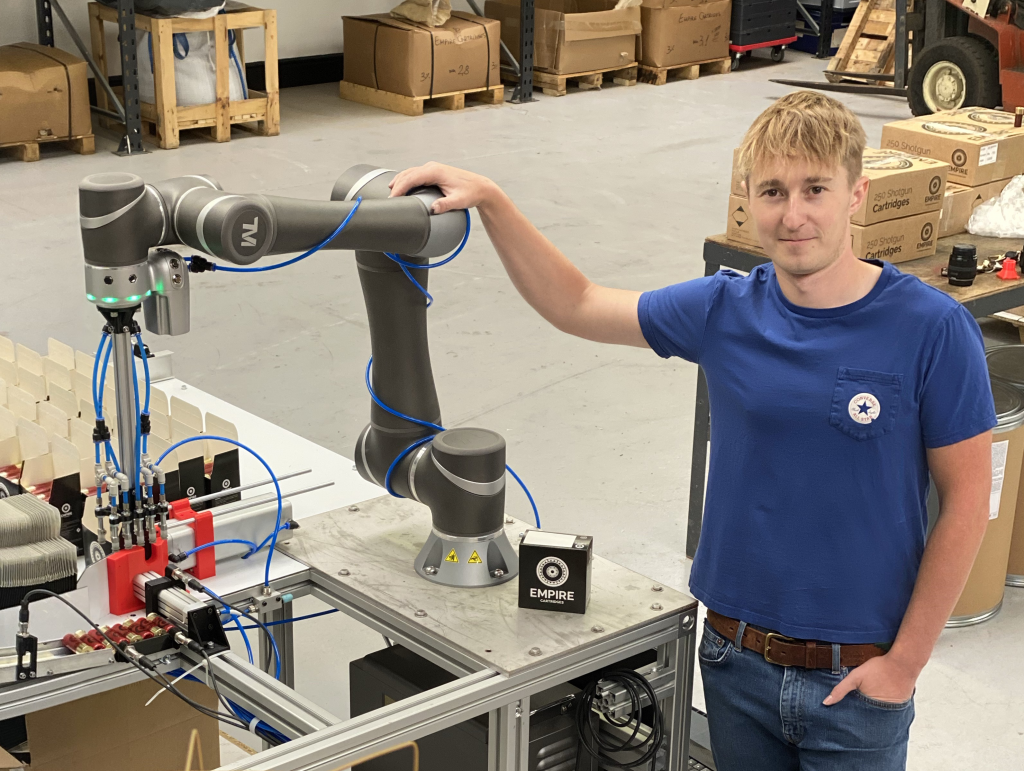

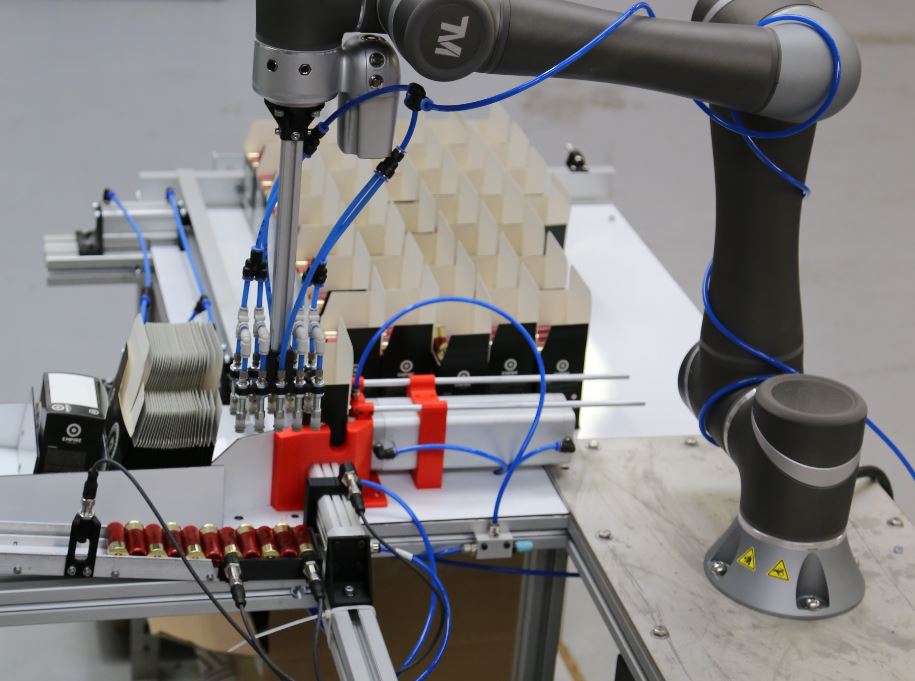

Image Gallery

Showcasing the fully automated production line in action, from cartridge assembly to packaging.

Our Solution

Delivering a Fully Automated, High-Performance Production Line

A collaborative robotic arm (Cobot) was integrated into Empire’s enhanced manufacturing system to automate the final packaging stage. Previously performed manually, this process is now handled by the Techman TM5 Cobot, which efficiently lifts and packs five cartridges at a time. Working in harmony with Empire’s bespoke cartridge manufacturing machine and conveyor system, the Cobot completes a fully automated production line.

Results

Enhanced Output, Precision, and Operational Efficiency

Simon Plimbley from Morson Praxis, who has been working closely with Empire Cartridges to integrate the Cobot into their manufacturing process, shared:

“Having been appointed as one of HMK Robotics‘ Tier 1 suppliers for deploying the Techman TM5, it has been great to see our first Cobot in action, especially under the current circumstances.

“The support we have received from HMK, the UK distribution partner of Techman Cobots has been second-to-none and we look forward to continue building our relationship with them as an innovation partner for future expansions at Empire Cartridges as well as in specific markets that are looking to embrace Industry 4.0 or digitalisation.

“In addition to this, the level of engineering ability that Andrew Bond at Empire Cartridges has shown has been beyond impressive, he has designed all the conveyor system and 3D printed all the components to manipulate the cartridge positioning. After some on-site training with one of our Cobot Engineers, Ana Luketic, he has now successfully finished the project.

“Finally, I would like to thank Andrew and his father, George Bond, for the opportunity and the Made Smarter team for their valued support in helping Empire Cartridges get the necessary funding to embrace digital technology.”

Testimonal

Hear from the expert

Andrew Bond at Empire Cartridges, shared:

“The support from Morson Praxis was excellent and the interface on the Techman Cobot meant we could get it up and running within a couple of hours of having it delivered, it’s been a complete revolution for us and increased productivity by easily 50%.

“I would recommend anyone who has even just an inkling that they might have an automatable operation to get in touch with Morson Praxis and to look into a Techman Cobot, it really is the future of modern manufacturing in the UK.”